Mr. Shinao Naoyuki, President and CEO of Shiina Factory Co., Ltd., has chosen to incorporate our GCC LaserPro FMC 280 fiber-cutting machine into their operations. He graciously shared with us the motivations behind this decision, its various applications, and the significant advantages they have gained from its implementation.

Company Name: Shiina Factory Co., Ltd

Major Business Items: Manufacturing of metal accessories, components, nameplates, and engraving services

Location: Tokyo, Japan

GCC Products: GCC LaserPro FMC 280 laser cutter

Before laser machine: Background & Challenges

We are a specialized metal processing town factory for accessories, celebrating our 70th anniversary in 2020. Located in Adachi Ward, Tokyo, we have our in-house factory, handling everything from mold design to metal stamping and finishing. With 70 years of experience and knowledge, we can provide customized processing solutions to meet your needs.

One of the challenges we faced in metal stamping was the difficulty in handling intricate work and the problem of creating molds for small-batch, high-variety production. For small batches, the upfront investment from our customers was substantial, and with a high variety of products, the number of trial runs increased, making it challenging to meet customer demands.

Additionally, we experienced fluctuations (each period) in workload, where there were periods of low demand for metal stamping related works, leaving us with little to do. This uneven workload presented another challenge.

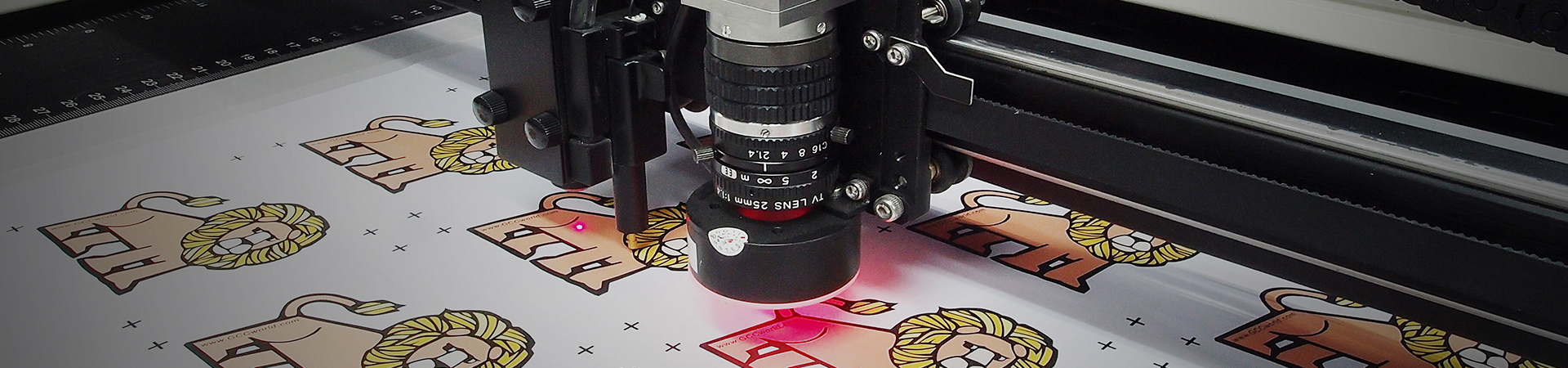

In this context, the FMC 280 laser cutter turned out to be the perfect fit for us, as it struck the right balance in size - not too small and not too large.

Additionally, the approval of domestic manufacturing support grants helped us reduce the initial costs, further encouraging our decision to adopt this technology.

Metal-cutting products such as accessory components and bangles.

Why introduce the laser machine and what are the main considerations?

We had always been interested in laser metal cutting machines, particularly because we heard that they were suitable for small-batch, high-variety production without the need for molds. However, many laser machines designed for metal cutting were large, and there were not many options available in the compact to mid-sized range that we were looking for.

In this context, the FMC 280 laser cutter turned out to be the perfect fit for us, as it struck the right balance in size - not too small and not too large.

Additionally, the approval of domestic manufacturing support grants helped us reduce the initial costs, further encouraging our decision to adopt this technology.

Metal-cutting accessory components (available for retail in Tokyo and Kyoto).

What results follow laser metal cutting machine installation?

The wider range of options available for presenting to customers has significantly increased our order volume. Thanks to the ease of sample production compared to molds, we not only receive orders for laser processing but also see the potential for larger-scale production. This has been a positive outcome of our laser processing capabilities.

The incorporation of laser cutting has indeed become a new cornerstone of our business. What's particularly notable is the balance it brings to our workload. Even when there's no metal stamping work, we have laser cutting jobs, and vice versa. This diversification has helped us maintain a more stable workflow.

Moreover, compared to machinery like metal stamping, which requires constant human intervention and carries the risk of accidents and injuries, laser cutting is inherently safer. We believe this has significantly improved the safety of our employees.

Plates for metal accessories.

Laser cut cat shape keychains.

Laser cutting processing products produced by Shiina Factory

As a small factory specializing in fittings metalwork, Shiina Factory excels in producing accessory parts.

|  |

Metal frames for resin-based accessories.

Laser engraving on spoons and forks.

What are your future prospects for the laser business?

We currently use nitrogen and oxygen as assist gases during laser cutting. We are currently using cylinders for this purpose, incurring costs. Therefore, we would like to introduce a nitrogen gas generation system to improve gas cost efficiency.

In the future, our ideal goal is to eliminate the need for molds entirely and process everything using lasers. This would achieve a balance between cost, time, and safety. To achieve this, we aim to increase our operational efficiency further to boost our revenue.

To read the original article, please click here.

*Please refrain from reproducing or distributing this article without obtaining permission from GCC.

Introduced laser cutting machine:

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done.

Further reading:

➤2023 Top-Quality GCC Laser Cutters & Cutting machines

➤Discover the Power of Laser Engraving

➤How To Make Laser Engraving Darker on Stainless Steel